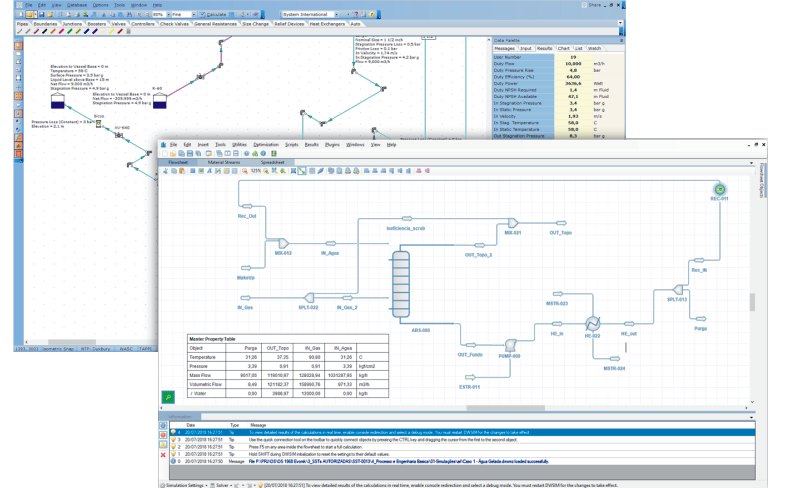

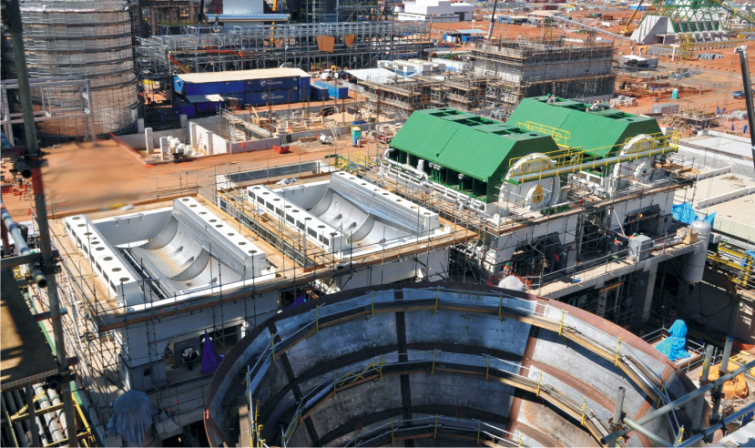

ENGINEERING UNIT aims to provide effective solutions by balancing technical, financial and economic

criteria. Every project takes into consideration client requirements and seeks the best alternative either for

feasibility studies, basic and detailed engineering, electromechanical erection supervision or services

performed in partnership with other A1 business units.

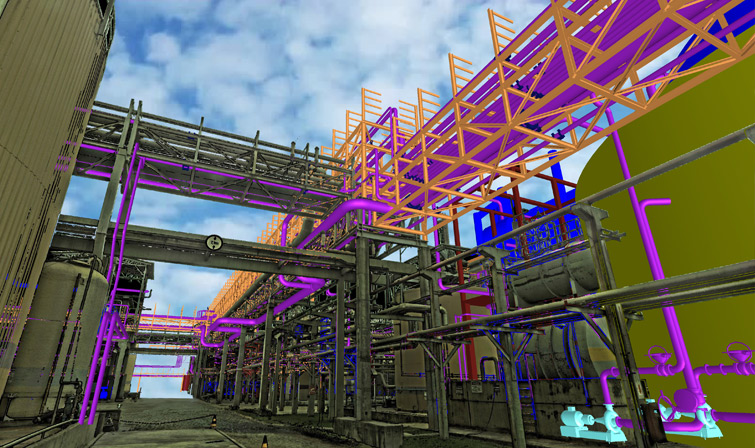

Most projects are built using 3D model technology, which increases data accuracy and significantly

eliminates interferences while also enabling collaborative and multidisciplinary participation of customers,

partners and suppliers.